In the mining business, your operation must meet critical demands and anticipate the unexpected every day to help reduce the costs of downtime. Challenging environments and destructive loads take their toll on your equipment.

Chesterton’s industry-proven hydraulic sealing solutions provide maximum value by extending the hours of operation between maintenance intervals of your equipment and increasing overall asset life. Our custom and turnkey cylinder repair kits combine proprietary polymer technologies with unique seal geometries to increase reliability and improve productivity.

Mega-Machines have to run constantly

Nowadays, gigantic hydraulic excavators shovel the valuable raw materials out of the ground and continuously load huge dump trucks. The mega machines are crucial for high mine production, but they have to run reliably. Any breakdown has a significant impact on production and means financial losses for mine operators.

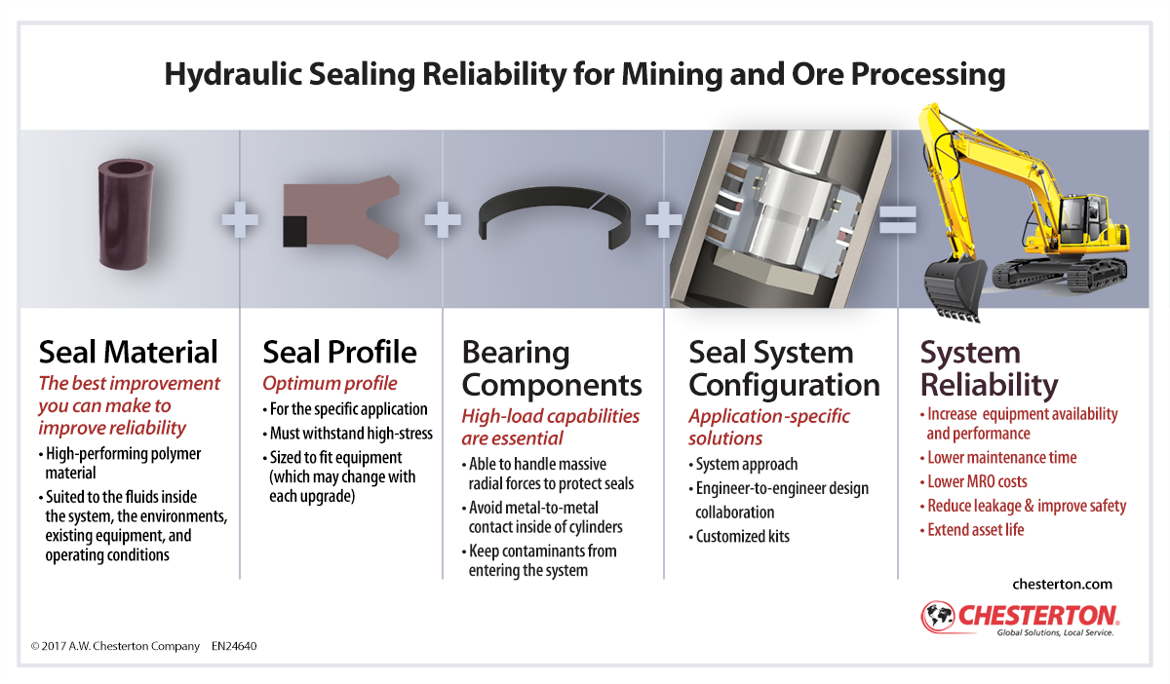

The hydraulic systems on these vehicles do amazing work: they dig, lift, lower and move extremely heavy loads in dusty environments. The performance, life and reliability of a hydraulic system is determined by several factors. In addition to the design of the components themselves and the choice of a high-quality hydraulic oil, it is the seals that ensure that the cylinders operate efficiently for a long time.

Our hydraulic sealing solutions effectively help to increase the productivity and service life of large machinery

Choosing high-quality polymer seals from Chesterton allows miners to:

- Increase equipment service life

- Increase operating hours between maintenance intervals

- Reduce breakdowns and costly downtime

- Reduce hydraulic fluid consumption

- Extend leak-free operating time

The quality of the selected sealing system determines the reliability and performance of the cylinders

The various hydraulic systems and their different functions, such as lift cylinders, stick cylinders, steering cylinders or bucket cylinders, also differentiate in the demands placed on the sealing system. This can be, for example, higher speed, higher pressure or excessive radial load.

Our sealing kit for heavy-duty hydraulic cylinders consisting of Wear Ring, Piston Seal, Rod Seal, Static Seal and wiper can efficiently improve the performance of the cylinder and the machine.

What does Chesterton provide?

We use high-performance, thermoset or even wear-resistant polyurethane material combinations that withstand high speeds, pressures and operating temperatures, have low friction, are highly elastic and have excellent tear and abrasion resistance.

Our custom-built sealing systems allow customization to meet existing performance requirements. „Mobile Mining Kits,“ individual high-performance cylinder repair kits have been proven to achieve longer off-highway machine uptime between maintenance intervals. These kits help companies control costs and maintain your profit margins by optimizing the value of equipment investments.

Chesterton’s proprietary thermoset polymer technologies provide high abrasion and wear resistance. Our unique seal geometries are specifically designed to offset known sealing issues related to pressure spikes, side loading, contamination, and low pressure leakage.

Please get more information about the mining applications of our sealing technology:

Chesterton Blog „Reliability Matters“ – Hydraulicseals – Reliability for Mega Mining Hydraulic Excavators

If you would like assistance selecting the best hydraulic seal solutions for your specific cylinder application, feel free to contact our Ask the Expert desk.

You can also make a preliminary selection using our product selector. Our product consultants will gladly assist you in selecting the ideal product for your application.